Under Casing

Spinning

Under Casing

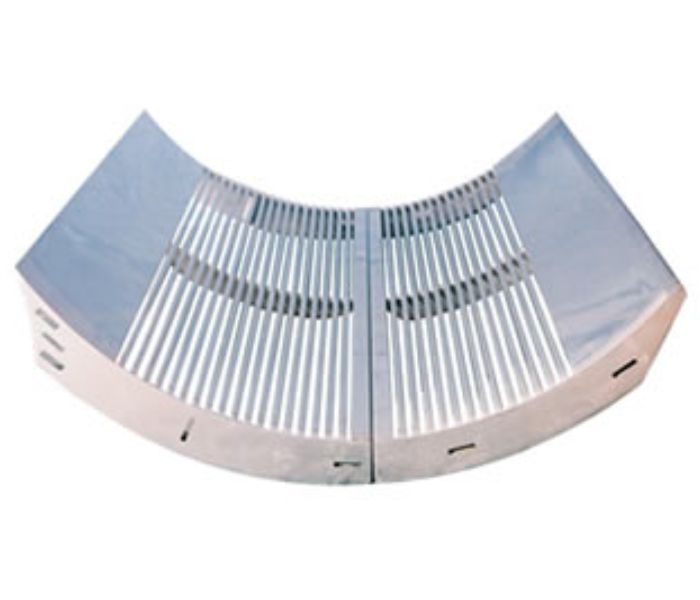

Sanmit introduces the undercasing suitable for various makes and models of carding machines.

Functions:

The main functions of the Undercasing are:

To cover the cylinder/Licker-in

To control the air currents

To control the movement of fibres

To allow heavy particles to fall down without loss of good fibres

To assist formation of even and Uniform layer of fibres for transfer to doffer.

The Undercasing are subjected to heavy abrasive actions, especially when spinning with trashy cotton or man-made fibres. Highspeed and presence of trash in material causes the undercasing to wear and thus it losses it smoothness. Also, cuts and burrs are formed on the projectionsof grids. This increases the frictional force and offers resistance to the material.

Manufacturing:

304-grade stainless steel with LASER cutting and special composition for soldering ensures:

Dimensional accuracy for perfect fitment and gauges

Matching of contours and curvatures

Smooth, polished and wear resistant surface

Advantages:

Avoids Occurrence of long thin faults

No fibre licking due to smooth surface

Prevents loss of good fibres

Perfect and uniform gauges

Longer life of undercasing

No distorted air currents

Undercasing And Carding Plates Available

For All Major Makes

And Models:

| Truetzschler | DK715, DK-740 |

| Crosrol | Mark 3, 4, 5A, 5B |

| Toyoda | CN, CE, TM - 8/S |

| Toyoda | MEIKIN |

| Howa | CMSK3, CMS80 |

| Whitein | - |

| Platts | - |

| Rieter | C1, C2, C3, C4 |

| Marzoli | C20, C40, C300 |

| Ming Cheng | - |

| LWW | 1/2, 1/3, 100, 300 |

| Tathamhs | 14148 |

| Hollingsworth | - |

| Rosique Card | - |