C-System

SANMIT SPINNING

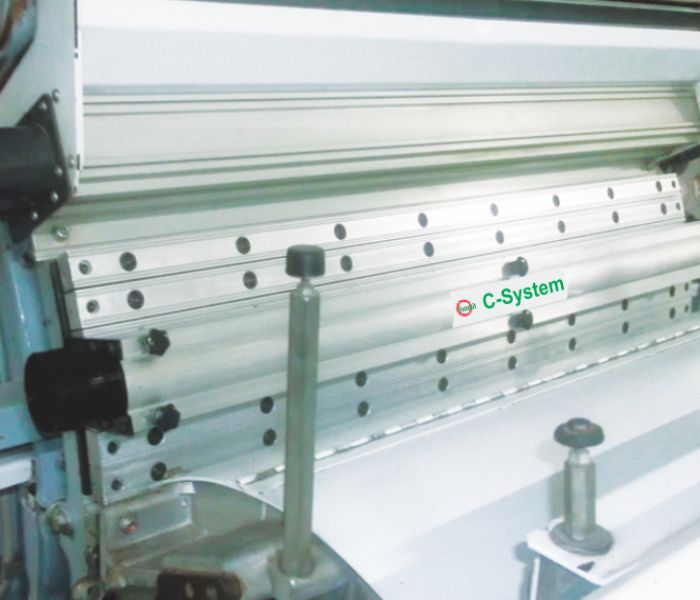

New Generation C-System

SFL (Above Lickerin)

Stationary flats are designed from coarser PPSI - bottom to Finer PPSI - top gives excellent pre opening of heavier fibre tufts. Mote knife and suction device removes trash particles and even distribution of fibres.

Salient Features:

Machine originality will be maintained during modification.

Imported high quality Stationary Flat Tops wires ensures yarn sliver quality and consistency in life.

It gives good parallelization of fibres and results reduces the carding strain and increases the life of cylinder wire and revolving flats.

Sturdy AI. base beam with Individual adjustment of Stationary Flats and mote knife makes accurate gauging which helps carding quality and production at higher speeds.

Smooth finish suction device helps to remove micro dusts, short fibres and motes and help to maintain clean suction in the machine.

No gap between each flat prevents dust liberation. No need for sticking forms between each flat.

Big suction device prevent air curling which ensures no suction chocking during card running.

Aluminium flats are made out of alloy grade smooth finish extrusion materials which gives flat stability.

Recommendation & Scope of Supply

** F - Flats/K-Knife

| Card Model | Above Doffer (SFD) | Above Licker-In (SFL) | Pre

Opening Combing

Segments (Under Licker-in) |

Process |

|---|---|---|---|---|

| D-K715 & D-K740 | 5 F + 1 K + Suction | 7 F + 1 K + Suction | 4 Segments + 2 K | Cotton/Synthetic |

| 9 F | 11 F | |||

| 5F + 1 K + Suction | 7 F +2 K + Suction | |||

| D-K760 D-K780, D-K800 & D-K803 (Single Licker in) | 6 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton/Synthetic |

| 7 F + 2 k + suction | ||||

| D-K800

- Twin Flat (Single Licker in) |

6 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton/Synthetic |

| D-K803

& D-K903 (3 Licker - in - Twin Flat) |

6 F + 1 K + Suction | 6 F + 1 K + Suction | - | Cotton/Synthetic |

| D-K760 (Cast Iron base C-System) | 6 F + 1 K + Suction | 7 F + 1 K + Suction | - | Cotton/Synthetic |

| Mk - 3 | 6 F + 1 K + Suction | 12 F + 1 K + Suction | - | Cotton/Synthetic |

| Mk-4 & Mk-5 | 6 F + 1 K + Suction | 8 F + 1 K + Suction | 4 Segments + 2 K | Cotton/Synthetic |

| C4 & C10 | 4 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton/Synthetic |

| C50 & C51 | 7 F + 1 K + Suction | 7 F + 1 K + Suction | 4 Segments + 2 K | Cotton/Synthetic |

| C60,C61 & C601 | 6 F + 1 K + Suction | 8 F + 2 K + Suction | - | |

| LC300,

300A 300A - V3 & 300A - V4 |

4 F + 1 K + Suction | 8 F + 2 K + Suction |

Economic Model Combing Segment Full Set |

Cotton/Synthetic |

| 6 F + 1 K + Suction | ||||

| C.1/2,C.1/2a,C.1/3 (Economic model) | 6 F + 1 K + Suction | 3 F | Economic Model Combing Segment Full Set |

Cotton/Synthetic |

SANMIT SPINNING

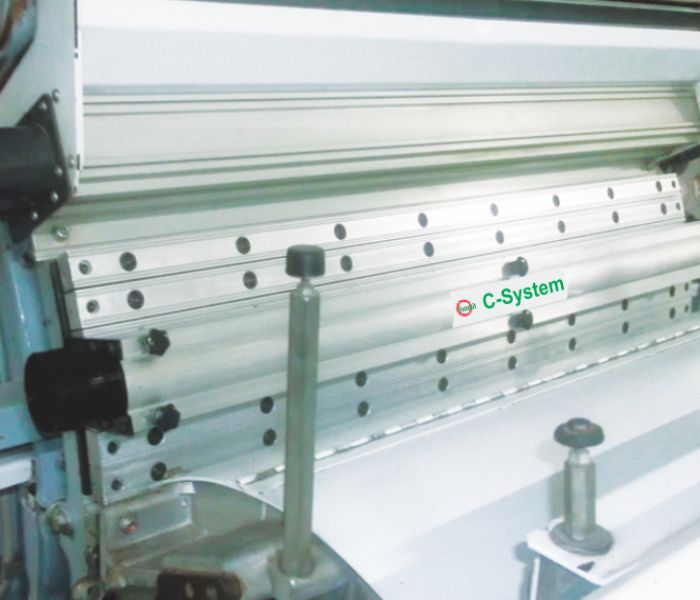

New Generation C-System

SFD (Above Doffer)

Finer PPSI stationary flats, mote knife and smooth finish suction device helps to improve classimate results.

Salient Features:

Machine originality will be maintained during modification.

Imported high quality Stationary Flat Tops wires ensures yarn sliver quality and consistency in life.

It gives good parallelization of fibres and results reduces the carding strain and increases the life of cylinder wire and revolving flats.

Sturdy AI. base beam with Individual adjustment of Stationary Flats and mote knife makes accurate gauging which helps carding quality and production at higher speeds.

Smooth finish suction device helps to remove micro dusts, short fibres and motes and help to maintain clean suction in the machine.

No gap between each flat prevents dust liberation.No need for sticking forms between each flat.

Big suction device prevent air curling which ensures no suction chocking during card running.

Aluminium flats are made out of alloy grade smooth finish extrusion materials which gives flat stability.

Recommendation & Scope of Supply

** F - Flats/K-Knife

| Card Model | Above Doffer (SFD) | Above Licker-In (SFL) | Pre Opening Combing Segments | Process |

|---|---|---|---|---|

| D-K715 & D-K740 | 5 F + 1 K + Suction | 7 F + 1 K + Suction | 4 Segments + 2 K | Cotton/Synthetic |

| 9 F | 11 F | |||

| 5F + 1 K + Suction | 7 F +2 K + Suction | |||

| D-K760 D-K780,D-K800 & D-K803 | 6 F + 1 K + Suction | 8 F + 1 K + 1 Suction | - | Cotton/Synthetic |

| 7 F + 2 k + suction | ||||

| D-K800 - Twin Flat | 6 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton/Synthetic |

| D-K803 & D-K903 | 6 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton/Synthetic |

| D-K760 | 6 F + 1 K + Suction | 7 F + 1 K + Suction | - | Cotton/Synthetic |

| Mk - 3 | 6 F + 1 K + Suction | 12 F + 1 K + Suction | - | Cotton/Synthetic |

| Mk-4 & Mk-5 | 6 F + 1 K + Suction | 8 F + 1 K + Suction | 4 Segments + 2 K | Cotton/Synthetic |

| C4 & C10 | 4 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton/Synthetic |

| C50 & C51 | 7 F + 1 K + Suction | 7 F + 1 K + Suction | 4 Segments + 2 K | Cotton/Synthetic |

| C60,C61 & C601 | 6 F + 1 K + Suction | 8 F + 2 K + Suction | - | |

| LC300,

300A 300-A - V3 & 300A - V4 |

4 F + 1 K + Suction | 8 F + 2 K + Suction |

Economic Model Combing Segment Full Set |

Cotton/Synthetic |

| 6 F + 1 K + Suction | ||||

| C.1/2,C.1/2a,C.1/3 | 6 F + 1 K + Suction | 3 F | Economic Model Combing Segment Full Set |

Cotton/Synthetic |

SANMIT SPINNING

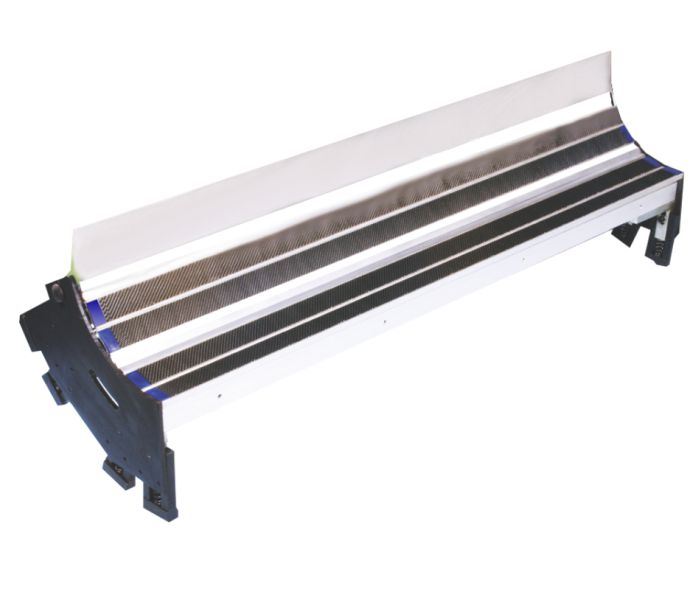

New Generation C-System

Salient Features:

Construction of assembly is replaceable slide(strip) type

Economic replacement for conventional araldite and punched sheets combing segments.

Sharp points gives better pre-openings that results in minimum loss of good fibres.

Aluminium combing bars are made out of alloy grade smooth finish extrusion materials which gives flat stability.

Machine original mote knives can be fixed without any alterations in assembly.

Easy replaceable and cost economic during replacement time

Suitable: C.1/2, C.1/2a , C.1/3, 100, 300, 300A & 300A -V3 / 300A - V4.

SANMIT SPINNING

New Generation C-System

Salient Features:

Construction of assembly is individual gauge setting and replaceable slide (strip) type.

Individual gauge setting ensures accurate gauging which results in better opening of fibre tufts in lickerin zone.

Sharp points gives better pre-opening that results in minimum loss of good fibres.

High quality hardened mote knives help to remove smaller and heavier trash particles results good reduction of neps in lickerin zone.

Easy replaceable and cost economic during replacement time.

Made out of high grade individual flat aluminium bars which gives more stability to ensure accurate gauging.

Suitable: D-K715, D-K740, MK4 & MK5